PRODUCTS

PROCESS

Concerntrate on tanning and varied quality checks

help us to deal with all kinds of orders.

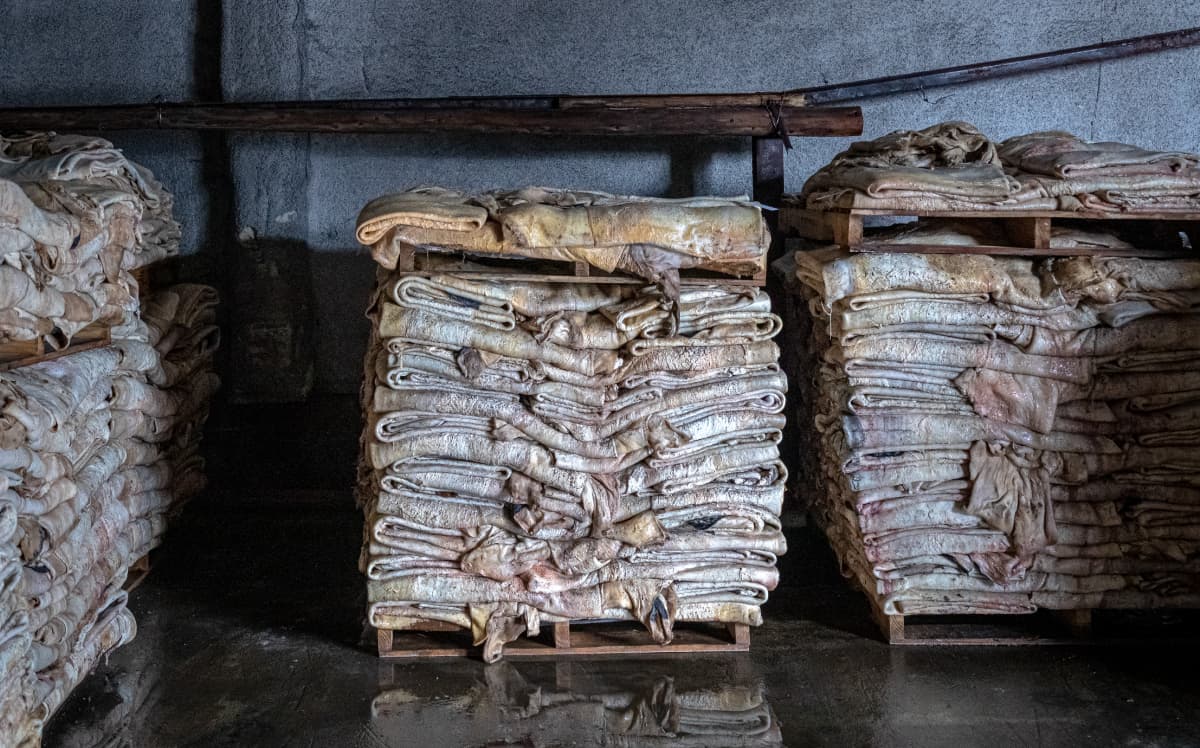

PROUD OF TANNING

Our uncompromising pursuit of tanning quality

Vegetable tanned leather

We use thick enough hide, quite rare tanning pits, mimosa from Brazil and take a month to make our hard, donnot strech vegetable tanned leather. During that period, we monitor the concertraiton and the temperature of the agent carefully. And during the drying process, we decrease the unevenness by adjusting progress speed.

Chrome tanned leather

We are one of those first companies that introduced chrome tanning techniques into this country. After a century's accumulation, we have reached our best solution about temperature, basicity of chrome and pH in the drum. And we carefully manage them everyday. Furthermore, as the conditions of each season are different, we also take them into account by checking the leather and do necessary adjustments all the time.

Wet white leather

In Japan, only we make this kind of leather now. It uses a special and eco-friendly tanning stuff. By monitoring the process thoroughly, we can get soft, heat resistant leather. Then we add vegetable tanning stuff during retanning, to adjust its feeling and characters, and finally we can make really strong heavy retanned leather.

QUALITY MANAGEMENT

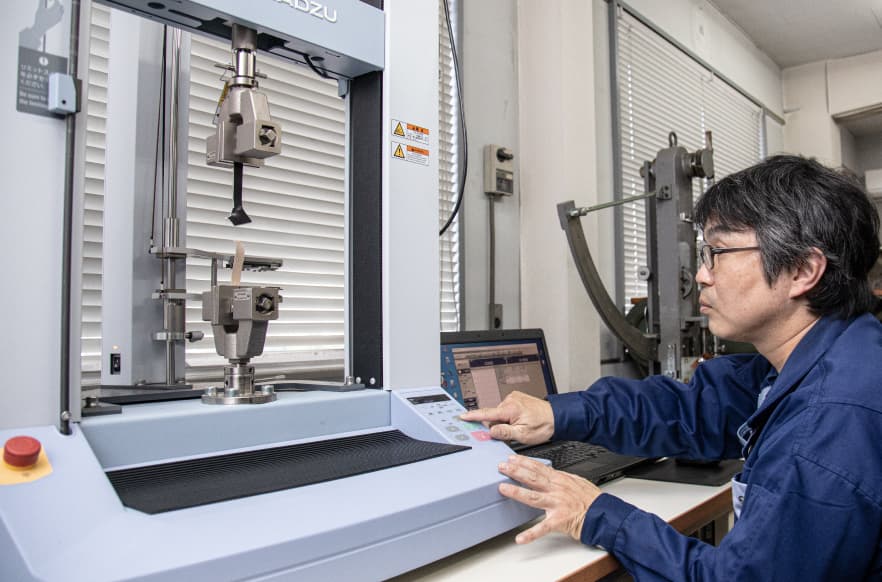

Quality check

Leather goods like shoes and bags, have different quality requirments depends on species, use and manufacture method. In Sanyo, we have our own physical property test room. There, we can do over 10 different tests, like "Breathability", "Tensile strength", "Ball-burst test", "Rubbing fastness" etc.. These years, we also make nonflamable leather, antibacterial leather and anti dry cleaning leather.

MAKE LEATHER

CONTACT

If you are interested in our leather,

or you have any questions about leather,

click here.

Contact us by E-mail

Contact us by telephone

Office hour: 8:00-17:00

Off-days: Saturday, Sunday and

Japan's National Holidays