REASON

INTEGRATED PRODUCTION

We control everything happen during leather manufacture.

We increase our quality and also your satisfaction and trust.

POINT

3 characters of our one-stop system

POINT 01

We do all procedures with our resourses to answer your varied requirements.

In Sanyo, all the procedures, from raw material, tanning to finishing, are conducted inside our own factory. As a result, we can control and do the little changes to thickness, softness, feeling, color or functionality according to instructions of each order. With our veteran technicians, perspicacity to catch the needs of tims, and our facilities bought from major suppliers like Italy and Spain, we make high quality leather meeting customer's images.

POINT 02

A constant and trusted supplier.

Since our establishment, thanks to our lagest integrated production system, we were able to provide costant supply. The species and amount of machines are the top class in Japan. To make sure a machine trouble will not affect manufacture, we have our own service department to do the daily maintenance. We also have a corperate factory overseas so we can make leather according to customers's needs against price and lead time.

POINT 03

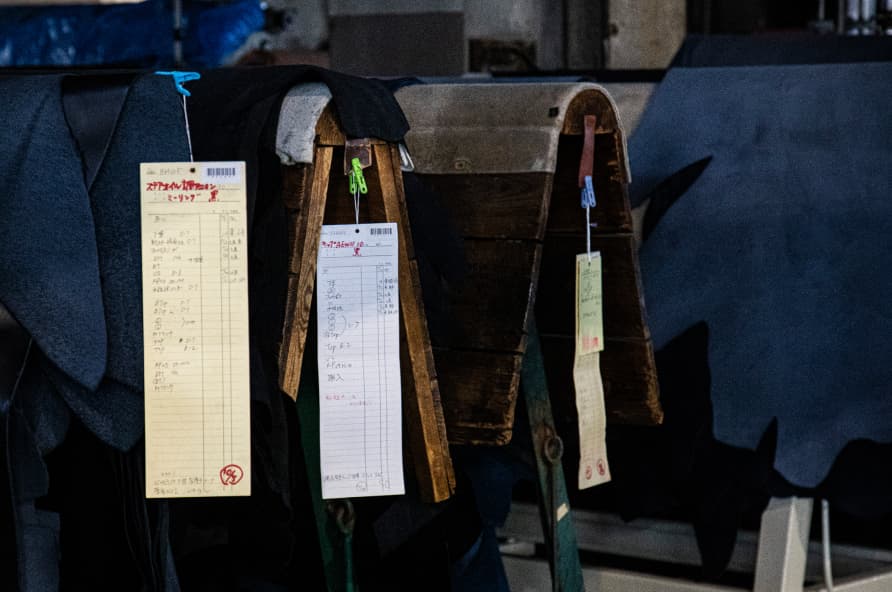

The traceability system let us know what's happening.

In Sanyo, the leather moves with cards that have detailed information such as raw hide's origin, the grade, and instructions of each procedures on them. Use them we can trace everything that is happening or happened. We also check and record all the usage information of chemicals and dyeing stuff. Finally, we put all these into database and manage them using bar codes. We are also working on building a system that can let our customers also know the progress of their orders.

CONTACT

If you are interested in our leather,

or you have any questions about leather,

click here.

Contact us by E-mail

Contact us by telephone

Office hour: 8:00-17:00

Off-days: Saturday, Sunday and

Japan's National Holidays